Frequently Asked Questions

Product Questions

What adapters will I need for my application?

How Do I identify My Grease Port Thread?

Grease fittings come in many different styles. There are two grease fittings that are most commonly used in the U.S. These are the 1/8″ NPT thread and the 1/4″-28 SAE thread. Based on our own sales data, the approximate frequency of the different grease port threads in the U.S. are:

| 60% of bearings | 1/8" NPT thread |

| 30% of bearings | 1/4"- 28 SAE thread |

| All remaining bearings (10%) | All other threads |

Grease Fitting Thread Gauge – The Easy Way

The easiest way to identify the thread on a grease fitting is to use a tool made specifically for this purpose. Grease fitting thread gauges are available from industrial equipment suppliers for around $50. Although convenient, you can identify your grease fitting thread without spending the money on this specialty tool.

Three Steps to Determining Grease Fitting Threads – Without a Thread Gauge

Measurement #1 – Straight or Tapered?

Measurement #2 – Thread Pitch

The number of threads per inch is known as the thread pitch. The best way to determine thread pitch of a grease fitting is to compare the threads to something with a known thread. A thread pitch gauge is the ideal tool for this but you can also compare the grease fitting threads to a known bolt thread, pipe thread, or another grease fitting.

Place the known thread against the unknown thread. If the two threads engage, the thread is the same. If they do not, the thread is different.

|

|

Measurement #3 – Thread Diameter

The last measurement you need is the outer or major diameter of the thread. A set of calipers makes this an easy measurement to take.

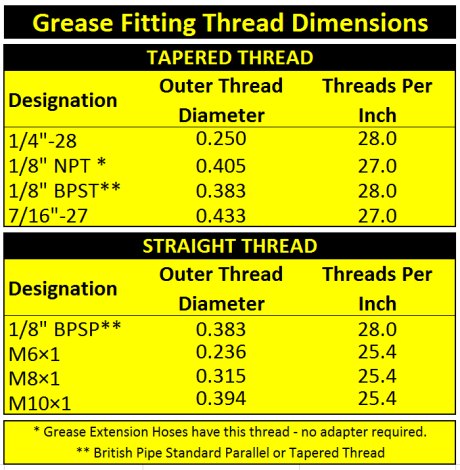

Finally, Find your Thread on the Chart Below

Dozens of different variations exist in grease fitting threads. We carry the necessary fittings and adapters to fit nearly every grease fitting port thread. These fittings cover more than 98% of the bearings found in the US. See the chart below to identify your grease fitting thread.

What Hose Ends are Standard on These Hoses?

The bearing end of our hoses have a 1/8″ NPT Male thread. This thread will fit roughly 60% of U.S. grease ports as is. We have thread adapters available for most other bearing threads.

The grease fitting (zerk) end of the hose has an 1/8" NPT Female thread and comes with a zerk fitting installed.

The grease fitting end of the hose includes a bulkhead fitting that can be mounted anywhere using our Extension Hose Mounting Rail or can be mounted into any 7/16″ hole in material up to 1/2″ thick.

How is Hose Length Measured?

We measure hose length from the bulkhead to the end of the grease port thread. Please see this sketch.

Can I Order Hoses Over Twelve Feet Long?

We limit our grease extension hoses to 12' for two reasons.

(1) At lengths over 12' there is a possibility of over-greasing bearings. As grease is injected into the reinforced rubber hose, the hose expands slightly, absorbing the grease. The hose then slowly contracts under it's own elastic tension, releasing the grease into the bearing over several minutes. If the lubrication tech is listening for the grease to enter the bearing, he will continue to pump grease into the hose until the bearing sound changes. This will result in too much grease entering the bearing over time. This issue can be overcome by injecting a known amount of grease into the hose at each lubrication.

(2) Grease is made up of oil and a thickener. Grease stored for long periods of time can separate. Longer hoses have grease stored for longer times because it sometimes takes years for grease to travel the length of the hose. Every time the lubrication tech adds grease, the grease in the hose moves a little further down the hose. The longer grease is stored, the more likely separation is to occur. Longer hoses have more capacity to store grease and therefore longer time in storage inside the hose.

We can manufacture longer hoses but want to make sure our customers are aware of these issues first. If you would like a quote for a hose assembly over 12 ft. long, please contact us here.

How Can I Contact Product Support?

We are 100% web based. The best and fastest way to get ordering support is to contact us here.

What Are Some Common Applications for Grease Extension Hoses?

Our extension hoses are useful anywhere grease fittings are difficult to reach.

Several common applications can be found here.

Do You Have Any Lubrication Tech Tips?

We're glad you asked. Yes, we have a collection of our best lubrication tech tips on our Grease Fitting Relocation Hose Tech Tips page.

Shipping Questions

Do You Ship to My Location?

We are currently shipping to all locations in the US, Canada, and Mexico.

What is Your Shipping Time?

Most orders ship within 2 days of your order being placed. Larger orders may require a longer lead time. We will notify you of any delays in shipping your order.

Can You Drop Ship to My Customer?

Yes. Just use your customer's address as the ship to address. We always include a packing list without pricing in our shipments.

However, please be aware that international orders require an invoice with pricing to be included with the customs forms.

Ordering Questions

What Payment Methods do You Accept?

We accept all major credit cards.

Can I Place a Telephone Order?

GreaseExtensionHoses.com is 100% web based. We do not have a bricks and mortar retail location. We can not take telephone orders because we can only process payment via our website.